Remote monitoring in industrial cold: not a luxury, but a necessity

25.07.2025

25.07.2025

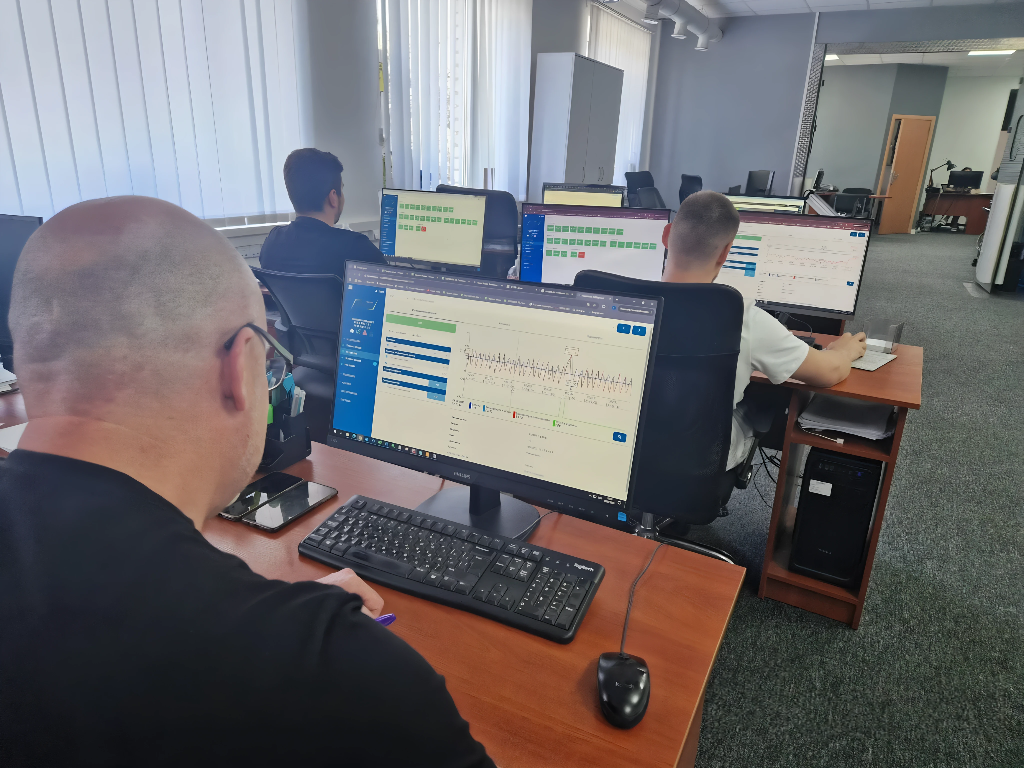

On hot summer days, the issue of keeping food fresh and ensuring stable cooling and storage becomes particularly acute. In conditions of unpredictable power outages, reliable refrigeration equipment is the key to maintaining quality and freshness. This is where RalcoTechnic comes to the rescue – a company that has been implementing projects in the field of industrial and commercial refrigeration for over 18 years, offering not only high-quality equipment, but also the possibility of

remote monitoring of its operation, which is an indispensable tool in the hands of a modern food product distributor.

- Remote monitoring is the process of controlling and managing technological equipment from a distance, usually using the Internet and other technological means, which allows you to track the status of devices, identify malfunctions and respond in a timely manner to force majeure circumstances affecting the operation of devices without being physically present at the facility.

What role does remote access and monitoring play in the management of refrigeration systems today?

In an era of instability, when blackouts, power surges and unpredictable circumstances have become our reality, remote monitoring is no longer just a tool, but a critical element of survival. Whereas stable equipment operation used to be the top priority, safety, energy efficiency and immediate response to any deviations are now at the forefront. Remote access is a watchful eye that never sleeps, allowing you to quickly identify threats, minimise downtime and, most importantly, save precious product stocks from spoilage.

What parameters can be controlled remotely?

The range of possibilities is impressive: from the temperature in each chamber to the pressure in the circuits, from the rhythm of the compressors to the vigilance of the defrost cycles, from emergency alarms to the status of the doors, from the coordination of the fans to a multitude of other important indicators. The monitoring capabilities are limited only by the complexity of the system and the number of sensors installed – and therefore, the potential for control is virtually limitless.

With the help of a remote monitoring system, a service engineer can detect a malfunction in refrigeration equipment faster than a salesperson in a store would notice it.

Notifications from the monitoring system are sent via:

- e-mail

- telephone

- SMS

- smartphone app.

Which manufacturers or systems does RalcoTechnic work with? And why specifically with them?

We are independent players on the market, free from the shackles of prejudice. Our experience covers a wide range of brands: Danfoss, Dixell, Carel, Eckelmann, EVCO, Eliwell, etc. Each manufacturer has its own unique strengths and weaknesses, so we approach the selection of solutions individually, taking into account the needs of a specific facility, the customer’s wishes, and the characteristics of each system. This flexible approach allows us to create projects that are distinguished by their quality and maximum efficiency.

What problems can most often be solved through remote monitoring?

The greatest value of remote monitoring lies in its ability to predict problems in advance. It allows you to detect the first signs of malfunctions or non-standard equipment operation in a timely manner. Whether it is an insidious refrigerant leak, a malfunction in the defrost mode, or an error in the control settings, everything is controlled by the system. This allows measures to be taken in advance, without waiting for catastrophic consequences. In addition, remote monitoring significantly reduces the need for service engineers to visit the site, as many problems can be solved remotely by simply adjusting the parameters.

An example of a real-life case where remote access helped to avoid a problem and quickly resolve it

One Friday evening, the meat storage freezer sounded an alarm indicating a gradual increase in temperature. The cause was a microcrack in the circuit, which led to a freon leak. Given that there are no staff at the facility on weekends, without remote monitoring, the problem would not have been discovered until Monday morning, when it would have been too late. Thanks to the timely alarm, we immediately contacted the customer and quickly repaired the malfunction, saving a significant amount of product from spoilage.

Customer response to the implementation of such systems. Do they have concerns about security or complexity of use?

At the beginning of the journey, many customers approach new technology with a certain degree of caution. They are concerned about the complexity of settings, the incomprehensibility of the interface, and the high cost. But when they see the first results – tangible savings, prevention of serious breakdowns – all doubts are dispelled. Remote monitoring is especially valuable for networked facilities or remote warehouses, where physical control of each element of the system is practically impossible.

How difficult is it to implement a remote monitoring system on existing equipment?

Implementing a remote monitoring system on existing equipment is a task that requires an individual approach, but it is entirely feasible. If the controllers are equipped with the appropriate interfaces, integration is quick and painless. Otherwise, additional sensors must be installed or new controller models must be purchased.

Who usually maintains such systems: the customer’s engineers, a service company, contractors?

The choice of the team that will service the system depends on the level of training of the personnel at the facility. Most often, specialists from RalkoTechnik or its reliable service partner take on remote support. In some cases, when it comes to large facilities with complex production dynamics, RalcoTechnic trains the customer’s staff so that they can manage the system independently.

Remote monitoring is no longer just a convenience, but a vital tool for effective management of refrigeration systems in modern retail and manufacturing environments.

Thanks to our specialists, this advanced technology is becoming more accessible and effective for every business, helping to preserve products, save money and ensure uninterrupted operation of enterprises.

Sales department

Sales department